Machine Vision

Automation in Manufacturing

Industrial processes are using more and more machine vision to provide inspection and recognition systems in high-speed manufacturing environments. In a production environment machine vision is used to:

- Correct production line defects

- Read barcodes and labels for inventory control

- Product tracking and tracing

Cambridge Electronic Industries 12GHz coaxial connectors and cable assemblies meet the CoaxPress CXP-12 standards, supporting bit rates of 12.5Gbps from the device to the host and with link aggregation, this can be up to 50Gbps (12.5×4). We are able to offer BNC and Micro BNC connectors for all speeds up to CXP-12 and DIN 1.0/2.3 for all speeds up to CXP-6.

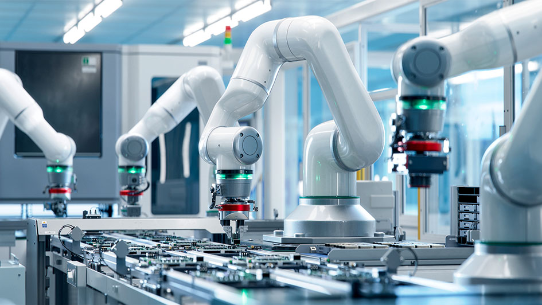

Product Assembly

Machine vision uses the 3D modelling designs generated by design software to allow the system to assemble the product to the exact requirement speedily and at a high quality every time. This process is used by manufacturing giants across the world to be able to manufacture the high demand for their goods. The machine vision model coupled with machine learning helps to monitor the automatic machinery and human workers’ interaction, to ensure that the most efficient assembly process is being used. This automated factory scenario can also help to avoid product recall situations, due to the strict assessment criteria put on each product as it moves through the factory.

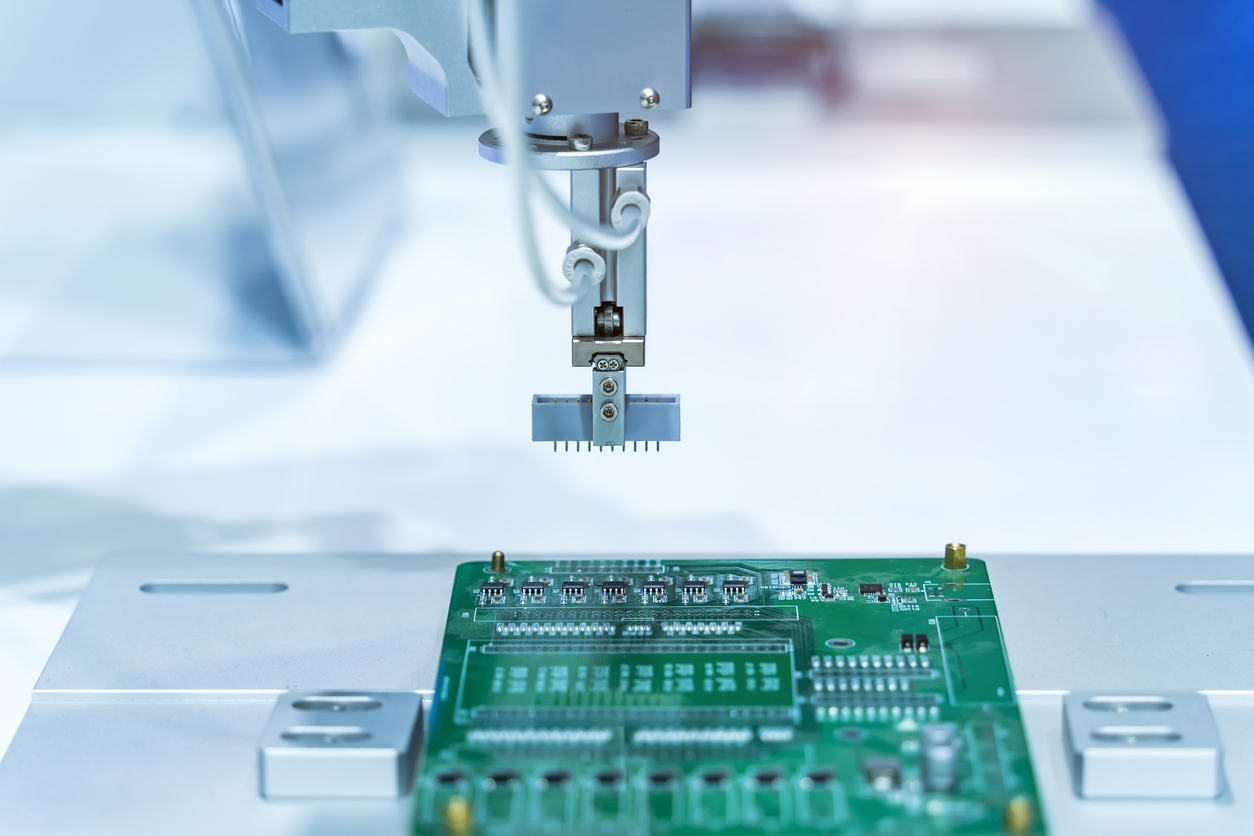

Detection of Defects

Large scale manufacturing sites often struggle to achieve 100% accuracy in defect detection in their goods. With a camera and frame grabber based diagnostic system, they can collect the data in real-time and analyse the results required for the expected quality of a product and show where a defect has occurred and remove this item from the system before packaging. This is particularly good when identifying minute defects in a production line where the speed and size make identification far superior to that of the human eye.

Packaging Standards

Machine vision used in a packing scenario offers the user the ability to get their product packaged to their specification the first time. This may be in the number of items packaged into each product or the orientation of the labelling, through to barcodes and traceability. Machine vision is helping manufacturers to prevent mistakes being made during the packing process and ensuring the consumer has the same high-quality product they expect when they purchase an item.

With the increasing use of machine vision in a broader spectrum of diversifying marketplaces, Cambridge Electronic Industries are uniquely placed to offer both design and manufacturing capability for any new equipment designs or systems installation.

12GHz Micro BNC Range

With the limitation of speed within the DIN 1.0/2.3 connector profile, our range of Micro BNC connectors is perfect for designs that need to offer maximum bit rates in a small profile. We have been working for many years with companies who have been developing frame grabbers and cameras for use in the machine vision environments and have introduced these connectors to the market to allow increased packing densities, making the end design as small a profile as possible, but with full CXP-12 capability. These connectors are available as part of our Micro BNC stock range, which has styles for all applications, including cable mounted versions.

Xtensa CXP Repeaters

Cambridge Electronic Industries introduced the world’s first CXP repeater and our new Xtensa range in 2021. The Xtensa Repeaters are plug and play devices which provide a cost-effective copper alternative to a fibre system, whilst drastically increasing the connection length at a given bit rate between the host and device. The repeaters require no external power supply as it uses Power over CoaXPress (PoCXP) technology, which can also be used to power other devices in the link, offering an improvement of functionality over a fibre system.

The simplicity of the plug and play repeaters with their compact design allows them to be inserted discreetly into a production environment without redesign of the plant or equipment. It can also be used multiple times in a single connection as long as the system designer observes the power budget requirements.