Thermal

With climate change an increasingly prominent global concern, the need for thermally stable connections has never been more important. Maintaining reliable connectivity requires components that can withstand fluctuating temperatures and challenging environmental conditions. In some applications, elevated temperatures are the norm and may be accompanied by extreme humidity, dust, or other environmental stresses.

The case studies below highlight just a few examples of the specialised solutions that Cambridge Electronic Industries has provided, offering both expert guidance and tailored manufacturing to meet these demanding conditions.

Product Inspection

Cambridge Electronic Industries’ cables are used within a machine-vision product inspection line for glass bottle production. The manufacturer aims to detect and correct defects at high speed (CXP12) early in the production process, therefore the bottles must be inspected while they are still hot.

Occasionally, hot bottles fall from the production line and can land on nearby cables, burning through standard cable jackets. To address this, we incorporate an additional high-temperature protective sleeving. This enhancement provides continuous thermal protection up to 260°C, with splash-resistance capability up to 1200°C, ensuring reliable performance even in these extreme conditions.

Mechanical Resistance

For some customers, we provide additional protective enhancements to ensure long-term cable performance. In large-scale industrial environments, heavy-duty processes generate significant heat, dust, and mechanical stress. To mitigate this, robust metal conduits can be used to encase and shield the cables. These conduits protect the internal circuitry and cable assemblies from harsh environmental factors that could otherwise cause damage or reduce system lifespan.

This added mechanical protection delivers high durability and reliability over many years of operation, making it an ideal solution for demanding industrial applications.

Harsh Environments

Our range of M-series connectors are engineered for use in harsh environments where reliable signal integrity is essential, even under demanding external conditions such as heat, moisture, and dust. With IP67 protection, these compact connectors provide exceptional resistance to environmental ingress when screw-mated, ensuring both a secure mechanical fit and a stable signal connection.

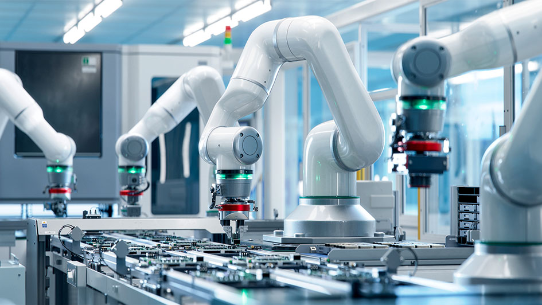

The circular outer design delivers robust physical protection, making the M-series the preferred choice for industrial applications where sensor signals must be transmitted reliably. These connectors are ideal for use in modern factory environments, where smart-manufacturing systems and AI-driven interfaces rely on accurate sensor data and machinery output signals.

Cable Looms

Cambridge Electronic Industries are happy to offer cable looms and assemblies from our head office in Waterbeach, which has a cable manufacturing facility. We use only manufacturers’ genuine parts, such as Souriau and Amphenol, as we know that these parts have the backing of the Military specifications as well as superior performance. All our Production staff are trained to the IPC 620 standards of cable loom production, to ensure that the finish of the cable is of the utmost quality, whilst each cable assembly is inspected and tested.

Bespoke Cables

As a designer of connectors, Cambridge Electronic Industries can also offer bespoke connector solutions. As well as designs for coaxial connectors we are also happy to look at other connector styles and have provided unique designs for military use. Working over a number of manufacturing sites, each with individual expertise, we are able to offer a full range of manufacturing options to take a design from concept to reality.