Featured Products

Core Range

Our core range of coaxial connectors offer a cost effective solution in a variety of profile options, including cable connectors. With the full precision 12GHz in BNC and Micro BNC options and 6GHz in DIN 1.0/2.3 capability and small profile, these connectors are perfect for new designs.

M Series Connectors

Offering a complete selection of M Series connectors in sizes M5, M8, M12, M16 and M20 versions, our range provide a high quality, IP67 rated range of connectors that can be used for voltage, power and signal applications.

Integrated Solutions

From wiring of cabinet panels to full integrated product solutions, we can assist in both hardware and software aspects of your project as well as product design and development.

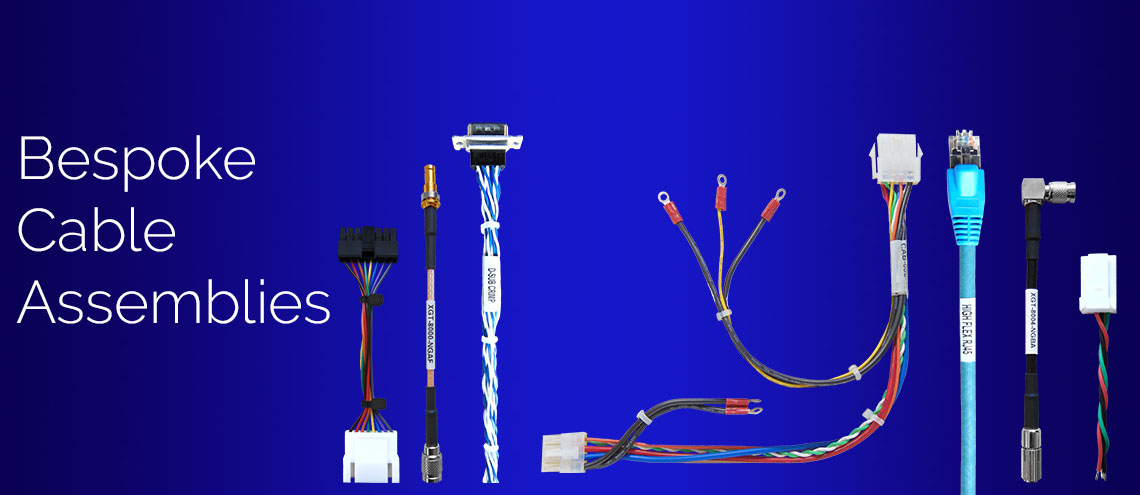

Bespoke Cable Assemblies

Specialists in Coaxial Cable assemblies, Cambridge Electronic Industries are happy to offer bespoke cable assemblies and looms to your design, using leading manufacturers components.

Stay Connected and Follow Us

Follow Us for the Latest Updates

Join us on these social media platforms to see the latest news and products from Cambridge Electronic Industries

Stay Connected

Sign up to stay informed of our upcoming product releases and other information.